Custom Powder Coating Process Explained: Steps, Benefits, and Applications

Powder coating has increasingly gained popularity over the years due to its numerous benefits compared to traditional paint application methods. Executive Coast 2 Coast Powder Coating provides top-tier powder coating services that deliver robust, efficient, and visually appealing finishes for a wide variety of materials. Our team is committed to providing professional services that prioritize customer satisfaction, environmental consciousness, and corrosion resistance. In this blog post, we will delve deeper into understanding the custom powder coating process, its advantages, and the various applications it provides value to.

First, let's explore the process of custom powder coating. It all starts with preparing the surface of the material that needs coating. This crucial step ensures that the powder adheres effectively and results in a long-lasting, uniform finish. This preparation typically involves cleaning the surface to remove any dirt, dust, grease, and potential contaminants. Depending on the material and its existing condition, we might use a chemical treatment, mechanical abrasion or a combination of both to achieve the optimal surface.

Once the material is appropriately prepared, the actual powder coating application begins. We spray an electrostatically charged powder material onto the surface, and this charge helps to hold the powder particles in place until the baking process is complete. The coated piece is then placed in a specialized oven and heated to the recommended temperature, causing the powder to melt and fuse, forming a smooth, continuous layer as it cools.

Now that you have an understanding of the process, let's talk about the benefits of custom powder coating. One of the most obvious advantages is its durability and longevity - powder coating offers exceptional resistance to chipping, scratching, fading, and corrosion, which means your products will look better and last longer without the need for constant maintenance. Additionally, the environmentally friendly aspect is a key point; powder coating does not involve the release of harmful solvents and has virtually no VOC emissions, unlike traditional wet paint. Furthermore, the range of finishes and colors available for powder coating is vast, allowing you to customize the look and feel of your products to meet your unique requirements.

Finally, let's discuss the applications where custom powder coating truly shines. The wide variety of materials that can be powder coated includes metals, plastics, composites, glass, and even wood. This impressive versatility makes powder coating ideal for industries such as automotive, aerospace, outdoor furniture, appliances, architectural, and many more. As a result, you can trust professional powder coating services like Executive Coast 2 Coast Powder Coating for durable, attractive finishes that last.

In conclusion, custom powder coating provided by Executive Coast 2 Coast Powder Coating is a process that offers numerous benefits, including enhanced durability, reduced environmental impact, and a wide range of finish options. It is also suitable for numerous applications, making it a highly valuable solution for many industries. Stay tuned for more posts expounding on these advantages and providing further tips on how to best use powder coating services for your projects.

Custom Powder Coating Process Explained: Steps, Benefits, and Applications

In our previous introduction, we gave an overview of the custom powder coating process, its benefits, and some of its applications. In this post, we'll delve even deeper into these areas and discuss why powder coating is an excellent choice for businesses and industries alike. Let's start by breaking down the individual steps within the powder coating process.

Step 1: Surface Preparation

As with any coating process, surface preparation is a critical step that contributes significantly to the final outcome. For powder coating, this is especially important because the adhesion of the powder to the surface relies heavily on proper preparation. The main objective is to remove any oil, grease, dirt, or contaminants that could interfere with the coating and provide a consistent, clean surface for the powder to adhere to.

Depending on the material being coated, various surface preparation techniques can be employed, including:

- Degreasing/cleaning: This step uses solvents or cleaning agents to remove grease and dirt from the surface.

- Shot blasting: High-speed abrasive blasting removes surface rust and scaling, creating a rough surface for better powder adhesion.

- Chemical etching: Acid or alkaline solutions can remove surface impurities and etch the surface, providing a keyed surface that aids adhesion.

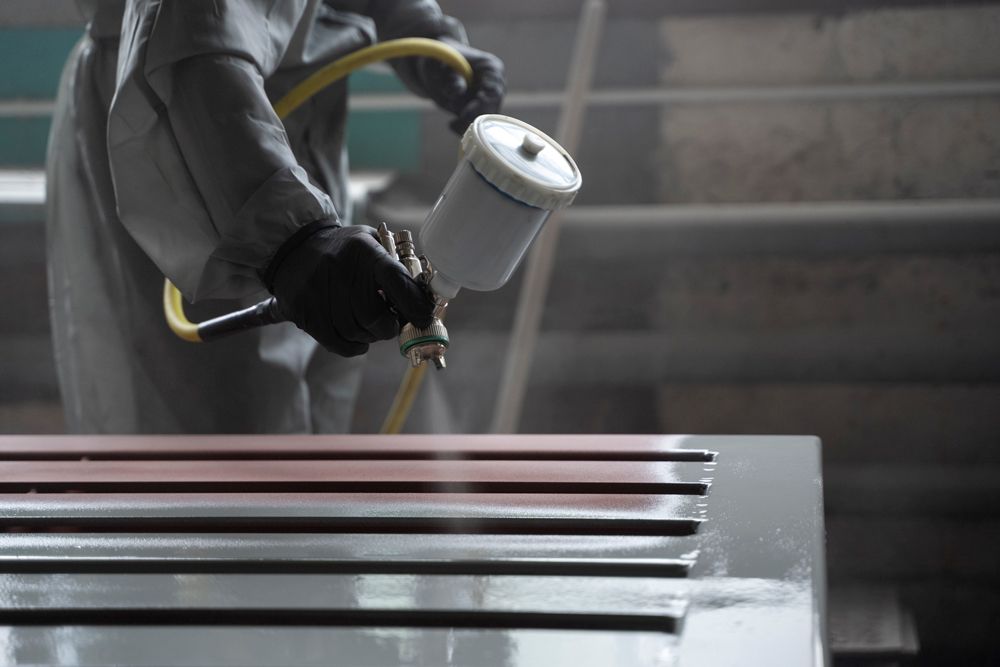

Step 2: Application of the Powder

After the surface is prepared, the powder can be applied using specialized spray equipment. The critical factor in this step is the use of electrostatic charge. By applying a voltage to the spray gun, the powder particles become charged, which attracts them to the grounded workpiece. This effect ensures that the powder adheres evenly and effectively to the entire surface.

The spray booth in which the application takes place is typically designed with filters and recovery systems to separate any excess or overspray powder, allowing it to be reused. This feature contributes to the efficiency and environmentally friendly aspects of powder coating.

Step 3: Curing the Powder

With the powder evenly applied, the workpiece is moved into a curing oven. It is important to note that the temperature and curing time parameters are specific to the type of powder being used. The heat causes a chemical reaction within the powder, cross-linking the polymer chains and creating a solid, continuous coating over the surface of the workpiece.

Once the curing cycle is complete, the workpiece is allowed to cool, resulting in a smooth, uniform, and durable finish.

Step 4: Quality Control and Inspection

The final step in the powder coating process involves inspecting each workpiece to ensure that the coating meets the necessary quality standards. Factors such as thickness, gloss, color, adhesion and more are assessed to ensure a high-quality finish that meets both industry requirements and customer expectations.

Benefits of Custom Powder Coating

Now that we have a thorough understanding of the process, let's reiterate the benefits of custom powder coating:

- Durability: Powder coatings are known for their exceptional resistance to chipping, scratching, corrosion and wear, making them perfect for applications that require long-term protection.

- Environmental friendliness: With no volatile organic compounds (VOCs) emitted and minimal waste generated, powder coating is an eco-friendly choice compared to traditional wet paint.

- Variety of finishes and colors: With a multitude of colors, textures, and finishes available, powder coatings offer endless creative possibilities.

- Cost-effectiveness: Powder coating often results in a lower cost per unit compared to other coating methods, thanks to its efficiency and low waste generation.

Powder Coating Applications

As mentioned in the introduction, custom powder coating can be applied to a wide range of industries and materials, such as:

- Automotive: From wheels to engine parts, powder coating lends durability and unique finishes to automotive components.

- Outdoor furniture: Outdoor furniture can benefit from the weather-resistant properties of powder coatings, ensuring a long lifespan and vibrant aesthetic appeal.

- Appliances: Many household and commercial appliances, like washers, dryers and refrigerators, utilize powder coating to enhance their appearance and resist wear and tear.

- Architectural and construction: Powder coated aluminum extrusions and other architectural elements provide lasting color and protection against the elements.

Conclusion

Custom powder coating continues to grow in popularity due to its numerous benefits and wide-ranging applications. At Executive Coast 2 Coast Powder Coating, our commitment to customer satisfaction and environmentally friendly practices ensures that our powder coating services exceed both industry standards and client expectations. With a great understanding of the powder coating process, businesses can make an informed decision about whether it is the ideal solution for their unique coating needs. Get in touch with our team to discuss your next project and see how our custom

powder coating services in New Jersey can elevate your finished products.